Product Development

Design Engineering:

Our engineering staff specializes in designing devices, tools, test fixtures, and assembly equipment related to disposable and reusable medical markets such as:

- Plastic and rubber tubing cutting equipment

- Tubing expanders and heated expanders optimized for plastic and rubber tubing

- Equipment for automatic insertion of barbed fittings into plastic and rubber tubing

- Surgical tool sets and devices related to heart valve replacement

- Class 10,000 clean room pass through windows (automated and manual)

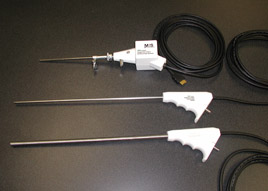

- Ultrasonic surgical cutters and aspirators and assembly sets - 2 patents

- Electro-surgical pencils

- Argon gas-assisted coagulation hand pieces

- Ambulatory infusion pumps

- Syringe infusers - patented

- Multidose syringe mechanism - patented

- Autoinjection syringe devices - patented

- Pharmacy compounders and peristaltic pumps

- Automatic syringe filling equipment

AMT's engineering department also has experience the following areas:

- Multi-axis (rotary and linear) laser etching systems

- Computer chassis/rack systems

- Gravity measurement devices

- Flatness checking robotic device for mil spec concrete floors

- Pneumatic and electro/mechanical fixtures and testing equipment

- Hand tools and simplistic assembly fixtures

Product/Automation Development Process

Project Overview:

AMT's phased development approach includes a concept phase, design phase, manufacturing phase, and a validation phase.

- Concept Phase:

The concept phase is where AMT develops a working concept along with a detailed schedule and the functional requirements document. At the conclusion of this short phase AMT will present a minimum of 1 ea. concept for Customer approval. - Design Phase:

During the design phase AMT will complete the CAD layout and perform appropriate engineering analysis to ensure structural rigidity. Additionally, AMT will generate an assembly model and detail drawings using Solidworks. AMT will present a complete set of detailed drawings of the fabricated parts including an assembly drawing with bill of materials at the end of the design phase. Upon gaining Customer approval AMT will begin the manufacturing phase. - Manufacturing Phase:

The manufacturing phase will include machining of fabricated parts in AMT's machine shop, procurement of purchased parts, and full electro/mechanical assembly of the device. The fabrication techniques, i.e.: cnc milling, cnc turning and welding will conform to aerospace standards of tolerance and quality. AMT will assemble the device and verify basic operational parameters to complete the manufacturing phase. - Validation Phase:

The validation phase is where AMT completes a thorough verification of operational parameter and certifies that the device meets the specifications per the functional requirement document (FRD). AMT solicits the Customer for final acceptance of the device. AMT has an outstanding record of On-Time Delivery and Customer Satisfaction. We always give the strongest of efforts to provide a high standard of professionalism and performance.